CFS product introduction

CFS overview

CFS (Concord Filter Solution) is clean room application units, The full name is Fan Filter Unit. Which integrated with both US’s HV made high efficiency air filter and German EBM motor, It is compatible to any ceiling keel shape based on different structural design. It can provide high cleanliness class ranging from 100 to 1. It has been widely used to provide the best air quality in clean room industries e.g.: semiconductor industries, microelectronic industries, optical industries, microorganism industries etc. Through advanced research and test facilities, we guarantee the quality of our FFU products and make sure that we can always deliver what we promised.

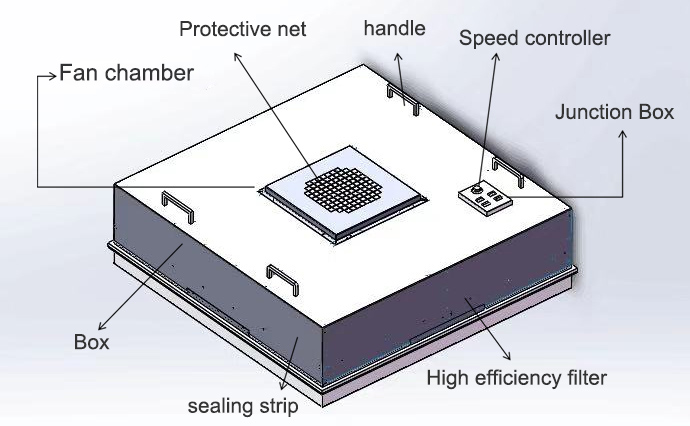

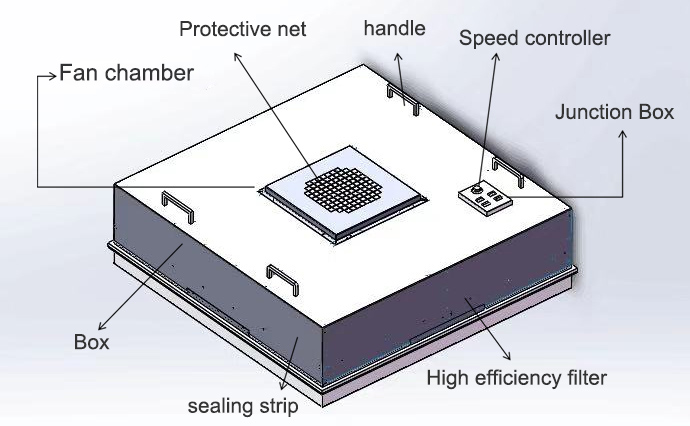

CFS structure

CFS features

Advanced performance and structural design. Applicable to any clean room.

Small volume, space-saving.

Specially designed inner diffusion plate for uniform air pressure and uniform air outlet velocity.

Specially designed air inlet point and air duct, low pressure drop and low noise, silencing cotton is not necessary.

high quality fan and high efficiency motor, low power consumption, power saving.

Installation of FFU

Make sure the unit is always in vertical position during delivery, unloading and installation.

The unit will be packed with multiple protective packaging during delivery. Please use forklift during unloading.The unit is not applicable to humid, smoky, oily and dusty area.

Do not expose the unit to area with high acid and alkali environment to prevent corrosion.

Enough air inlet space should be prepared during installation for uniform air flow.The unit will be installed at the ceiling keel along with HEPA filter. The sealing will be dependent on its own weight.

Maintenance

Observe the operating conditions of the unit. Turn it off if there is any abnormal condition.

Do not dissemble the electrical components.

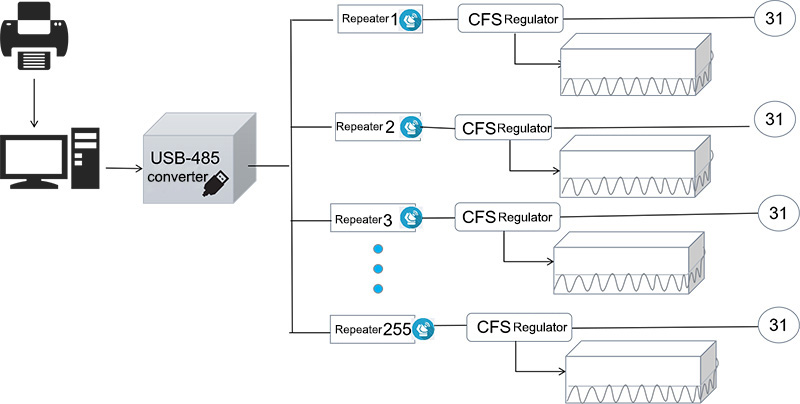

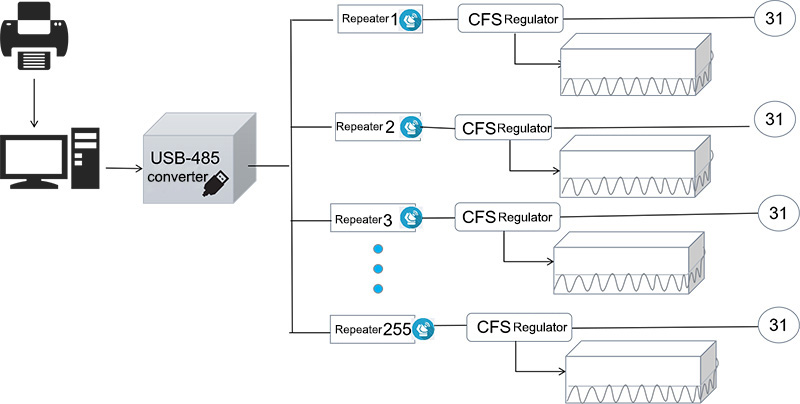

Control system

The LISA software will controlled all FFU and its features are:

1.Max monitor and control ≤7905 FFU.

2. RS485 communication mode.

3. All FFU can be divided into 255 groups, and each group can have 31 CFS.

4. Control one or all of the FFU at the same time by instructions.

5. Diagnose error information, locate errors and analyze.

6. Control operation, alarm and speed are automatically displayed.

7. In the case of computer or data transmission interruption, FFU still runs according to the obtained data.

485 communication control schematic

CFS performance data sheet

|

Unit size |

Motor |

Dimension L*W*H |

Active filter area m2 |

Max flow rate

m3/h |

Max Watts @ Max m3/h |

Wind velocity @90fpm |

Total static pressure@0.45 m/s |

sound dBA |

Unit Weight Kg |

|

2*2 |

EC |

570*570*285mm |

13.4 |

515 |

120 |

0.45 |

110 |

52 |

26.9 |

|

AC |

570*570*285mm |

13.4 |

515 |

140 |

0.45 |

110 |

52 |

28.2 |

|

2*3 |

EC |

575*875*285mm |

20.9 |

804 |

120 |

0.45 |

110 |

52 |

30.3 |

|

AC |

575*875*285mm |

20.9 |

804 |

140 |

0.45 |

110 |

52 |

31.8 |

|

2*4 |

EC |

1175*570*285mm |

28.3 |

1088 |

150 |

0.45 |

110 |

52 |

33.2 |

|

1219*610*285mm |

31.5 |

1214 |

180 |

0.45 |

110 |

52 |

34.6 |

|

AC |

1175*575*285mm |

28.3 |

1088 |

150 |

0.45 |

110 |

52 |

33.2 |

|

1219*610*285mm |

31.5 |

1214 |

180 |

0.45 |

110 |

52 |

34.6 |

|

3*4 |

EC |

1175*875*285mm |

44.2 |

1698 |

200 |

0.45 |

110 |

52 |

37.6 |

|

AC |

1175*875*285mm |

44.2 |

1698 |

200 |

0.45 |

110 |

52 |

38.9 |

|

4*4 |

EC |

1175*1175*285mm |

60.2 |

2319 |

220 |

0.45 |

110 |

52 |

61.2 |

|

1219*1219*285mm |

65.1 |

2502 |

240 |

0.45 |

110 |

52 |

63.4 |

|

AC |

1175*1175*285mm |

60.2 |

2319 |

220 |

0.45 |

110 |

52 |

61.2 |

|

1219*1219*285mm |

65.1 |

2502 |

240 |

0.45 |

110 |

52 |

63.4 |

Performance Notes:

1. Units are tested in accordance with IEST RP-CC002.2, Recommended Practice for Unidirectional Flow Clean-Air Devices.

2. Sound levels were measured with unit installed in a T-Bar ceiling, with gasket, in a standard room. Sound levels in dBA were measured at a distance of 30 inches from the filter face, with the unit set to produce 90 fpm average face velocity. (Note that data is for a clean filter only. If fan speed is increased to compensate for filter loading the noise level will increase.)

3. All data is based on a unit with a clean filter.

4. 90 fpm values are based on active filter area.

5. Heat Gain: BTUh = Watts x 3.413.